Green Mountain Boys

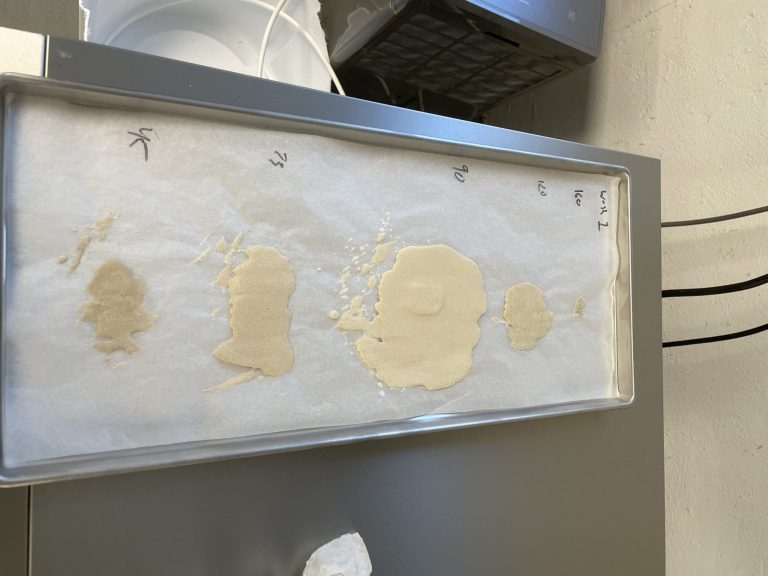

Using cold water extraction techniques we being to extract the trichomes from the plant and collect the rosin before spreading it out onto a tray destined for the freeze dryer.

After setting the rosin into the freeze dyer, it takes an expert eye to ensure that enough moisture has been removed in order to make the next steps proceed smoothly, while still ensuring a high quality product.

Passing the rosin though a fine mesh, while maintaining a proper cold temperature, is important for this step. After this step is completed we end up with high quality bubble hash.

After the rosin has been sifted and stored in the proper conditions the final step is adding pressure and heat to the product so that it can form a live rosin concentrate.